In the last post of this series we discussed why blaming the magnetic beads for faulty biomagnetic separation can be a big mistake. The main reason is that the problem may be the magnetic rack rather than the beads.

Being aware of the significance of the biomagnetic separation system is not enough. Another common mistake is to assume that a bigger magnet will increase the magnetic force. Magnetic force, however, does not depend on the magnetic field but on the magnetic field gradient. If the prism shape is too big with respect to the working volume, the magnetic field becomes homogenous and the force is greatly weakened, the result of which is: excessively long separation times and/or higher losses. If the prism is small, both the magnetic field and the magnetic field gradient decay very quickly with distance, and the force is unable to attract the beads which are farthest away. Even worse, the force close to the magnet is too high, causing irreversible aggregation.

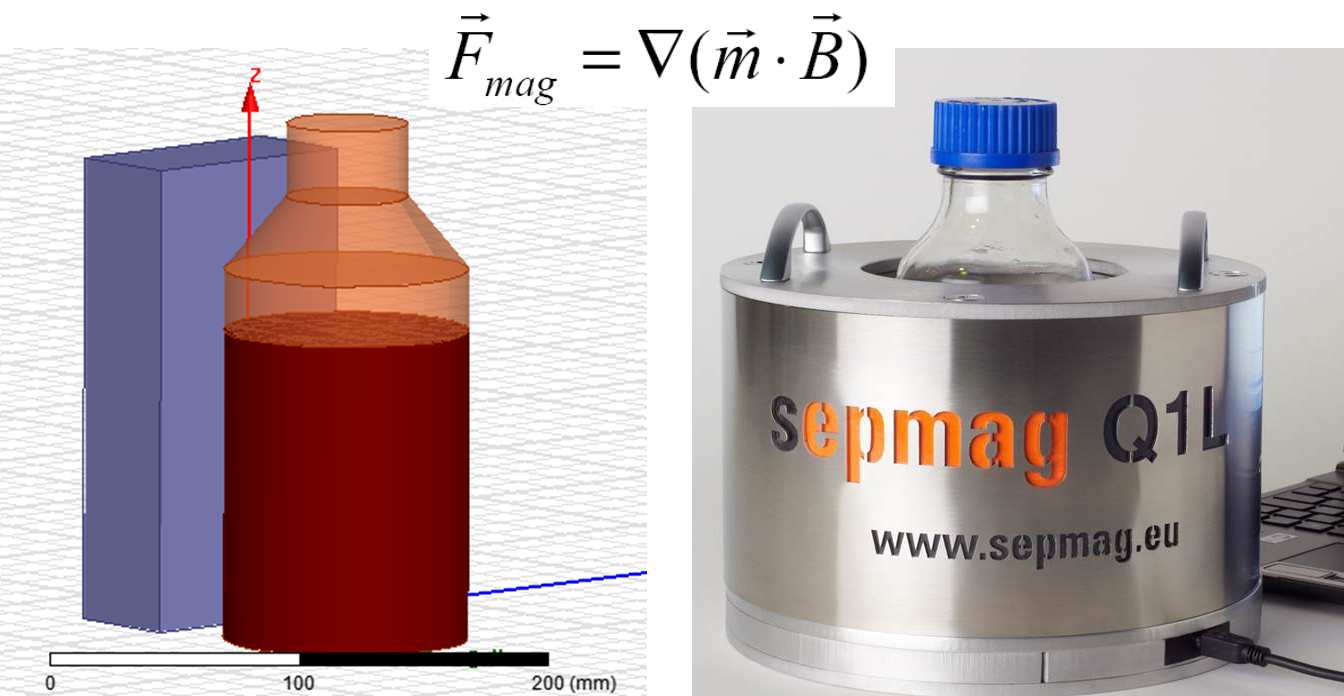

This is best illustrated with an example. Let’s compare what happens with a large magnet and with an advanced biomagnetic separation system, both using the same amount of permanent magnet.

Permanent magnet prism (left) and advanced biomagnetic system (right) for separation up to 1 liter of magnetic bead suspension. Both devices use the same number of permanent magnets.

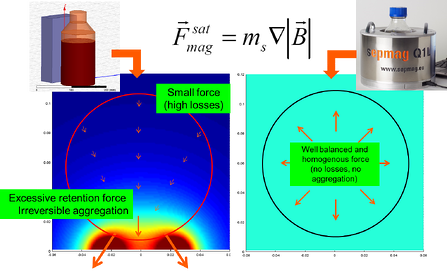

To compare these systems we need to look at the magnetic force. An easy way to do this is by looking at the magnetic field gradient maps. As the figure shows, the simple permanent magnet generates a very low gradient just a few millimeters away from the magnet while the force farther away from the magnet is very low. This means high bead and biomarker losses. Even with very long separation times, complete separation of the solid phase is almost impossible.

Remember to download our free guide Five critical mistakes in CLIA IVD-kits manufacturing to learn about all these mistakes:

Finding the optimal magnetic force

The optimal magnetic force is the value that simultaneously offers both quick separation and low losses; a retention force high enough to retain the beads when the supernatant is extracted, which is also mild enough to avoid irreversible aggregation. In this example, the cyan area represents the optimal value for the magnetic force. The region where the suspension works under the optimal conditions is just a tiny fraction of the batch volume. Nearer the prism, the force increases quickly and, consequently, there is a very high risk of irreversible bead aggregation. This risk is exacerbated by the long separation time required by this kind of magnetic separation rack.

Magnetic Force maps for a Permanent Magnet prism (left) and an Advanced Biomagnetic System (right).

In contrast, advanced biomagnetic separation systems use magnetic field profiles by generating homogenous magnetic force. This means the force is the same throughout the working volume. A higher force is generated over the beads farther away from the vessel walls. The magnetic beads move faster, reducing separation times and guaranteeing complete recovery of the solid phase and coupled biomarkers. In the retention area, the force is still the same. If the system is designed to obtain optimal values, the beads experience enough force to be retained during buffer extraction, but this force is still low enough so as not to generate irreversible processes.

Feedback from companies confirms these claims. A European company testing a SEPMAG Q1L reported the following results¨:

- 200 nm magnetic beads, suspension at 3%: Recovery of over 99% at the end of the cycle.

- 300 nm magnetic beads, suspension at 1%: Recovery of over 99.5% after six minutes.

- 500 nm magnetic beads, suspension at 1%: Recovery of over 99.5% after three minutes, both in water and organic buffer.

Magnetic bead manufacturer ReSyn Biosciences was even more enthusiastic and shared its satisfaction with the Biomagnetic Separation process improvements when using advanced systems, even when the magnetic beads were in a viscous liquid suspension on Facebook and Twitter.

Testimonials by Resyn Bioscience, a magnetic bead producer, regarding the use of Advanced Biomagnetic separation systems.

So, how can you avoid Mistake #2 (Use bigger magnets to avoid losses)? Think in terms of magnetic force rather than magnetic field, because there is no sense asking how many Tesla (or Gauss) are generated by a magnetic separation rack.

Remember that the force needs to be balanced correctly because excessive force can lead to irreversible aggregation problems. Choose the right force for the farthest areas, as well as the retention area.

As a general rule, we recommend you seek external expert advice, because IVD companies do not tend to be experts in magnetic design.

Related articles:

- Five critical mistakes when using Biomagnetic Separation in CLIA IVD-kits manufacturing

- How can we specify a Biomagnetic Separation Process?

- Mistake #1 in CLIA IVD-kit manufacturing: Blaming the magnetic beads